How Is A Brass Rubbing Made?

|

|

| Brass Facsimile |

|

The process of brass rubbing involves stretching a piece of specially-made paper over the deeply-etched brass plate (or the facsimile) and rubbing over the paper's surface with a hard crayon-type wax cake. These wax cakes have colors incorporated into them, such as white, black, blue, red, green and brown. Some even have metallic colors, such as gold, silver and copper to give a metallic sheen on the paper. By rubbing with these wax cakes, an exact copy of what is etched on the brass is created. The original rubbings were produced by using either black wax on white paper or gold wax on black paper; however, wax sticks are now available in several colors, including brown, blue, red, green, bronze, black and silver.

|

|

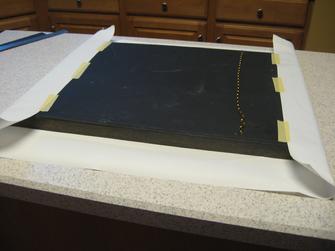

| The first step is to assemble your supplies....the brass facsimile, specialty paper, masking tape, soft cloth, and wax crayons. You also want to make sure you have a workspace that gives you good maneuverability and has excellent lighting. |

|

|

|

| One of the keys to a good, clear rubbing is to make sure the paper is wrapped around the brass and tightly secured so it will not move around during the rubbing process. |

|

|

|

| The next step involves slowly tracing the outline of the image using your index finger and following along the edges of the design below the paper. Some brasses have irregular or poorly defined edges, so those will need to be cut out once the rubbing is complete and re-mounted before framing for a clean look. |

|

|

|

| The art of brass rubbing is to do several "layers" of gentle rubbing, building up the intensity of the color each time until you achieve the desired result. Rubbing too hard or from different directions can result in ugly scratches and uneven coverage. |

|

|

|

| Once the desired result has been achieved, the rubbing will need to be wiped off with a soft cloth to remove any remaining wax particles that could smudge the design. If the edges were not raised adequately enough to keep from running off the edge (as is the case with this particular facsimile), the images will need to be carefully cut out and re-mounted on another piece of paper before framing. |

|

|

The creative process of rubbing a brass is indeed a learned art. Rubbing a clear and neat image is essential and not always easily achieved. Brasses must be rubbed in one direction only and with a steady, even pressure. The desired result comes from slowly building up the color and from systematically working a small section at a time in order to bring out all the small details in the engraving. Many brasses contain imperfections which should be replicated, as they are, in order to maintain the authenticity of the original brass.

|

|

| Finished Brass Rubbing |

|

The qualities of the brasses that determine how well they will reproduce are the smoothness of the plate surface and how deeply the engraved lines and edges are of the image. Some floor brasses have been so worn down over the years that the lines are very difficult to determine, and therefore it is much more difficult to achieve a professional result. These rubbings usually have to be cut out and remounted in order to have the desired clean lines and edges. Others have very deeply engraved details and edges that make them very easy to rub and achieve the desired result.

|

| Brass Rubbing Materials

Obviously, the most important ingredient necessary to create a brass rubbing is the brass plate itself or an authentic facsimile. The second requirement is a piece of specialty paper, in a color of your choosing. The original brass rubbings were produced in either gold wax on black paper or black wax on white paper. Vintage Design also has a large selection of colored papers which are no longer produced in the United Kingdom or elsewhere in the world. These colors include metallic silver, metallic gold, tan, royal blue, red velvet and olive green velvet. The papers are specially made for brass rubbing, with specific requirements for their pulp content and weight grade. The third material needed for the rubbing is the wax cake, available in both large heelball rounds and sticks. These wax cakes have color incorporated into them, such as white, black, green, and even metallic colors. Vintage Design offers a choice of ten wax colors, including three metallic ones. Other materials necessary for completion of a rubbing include masking tape, scissors, a soft brush, silk hosiery and cardboard.

|

|